Altia announces today that our HMI solutions have been integrated with Renesas R-Car Gen3e CR7 Reference Software. Already a longtime supporter of the Renesas R-Car Family, Altia continues our commitment to provide top notch support for Renesas R-Car Gen3e. Our latest code generation solutions enable fast boot time, dedicated support for functional safety operations, further simplified system architecture and overall reduced development costs for OEMs and Tier 1 suppliers designing and deploying integrated cockpits.

“Altia and Renesas have a long-standing history of collaboration in delivering powerful production-proven embedded graphics for automotive applications leveraging the Renesas R-Car Family. Based on our feature upgrade in R-Car Gen3e, Altia continues to demonstrate their leadership in the HMI software space by providing a unique code generation solution that gives our customers the power to deploy first rate graphics while supporting multiple GPUs and operating systems,” stated Naoki Yoshida, Senior Director, High Performance Marketing Digital Division at Renesas.

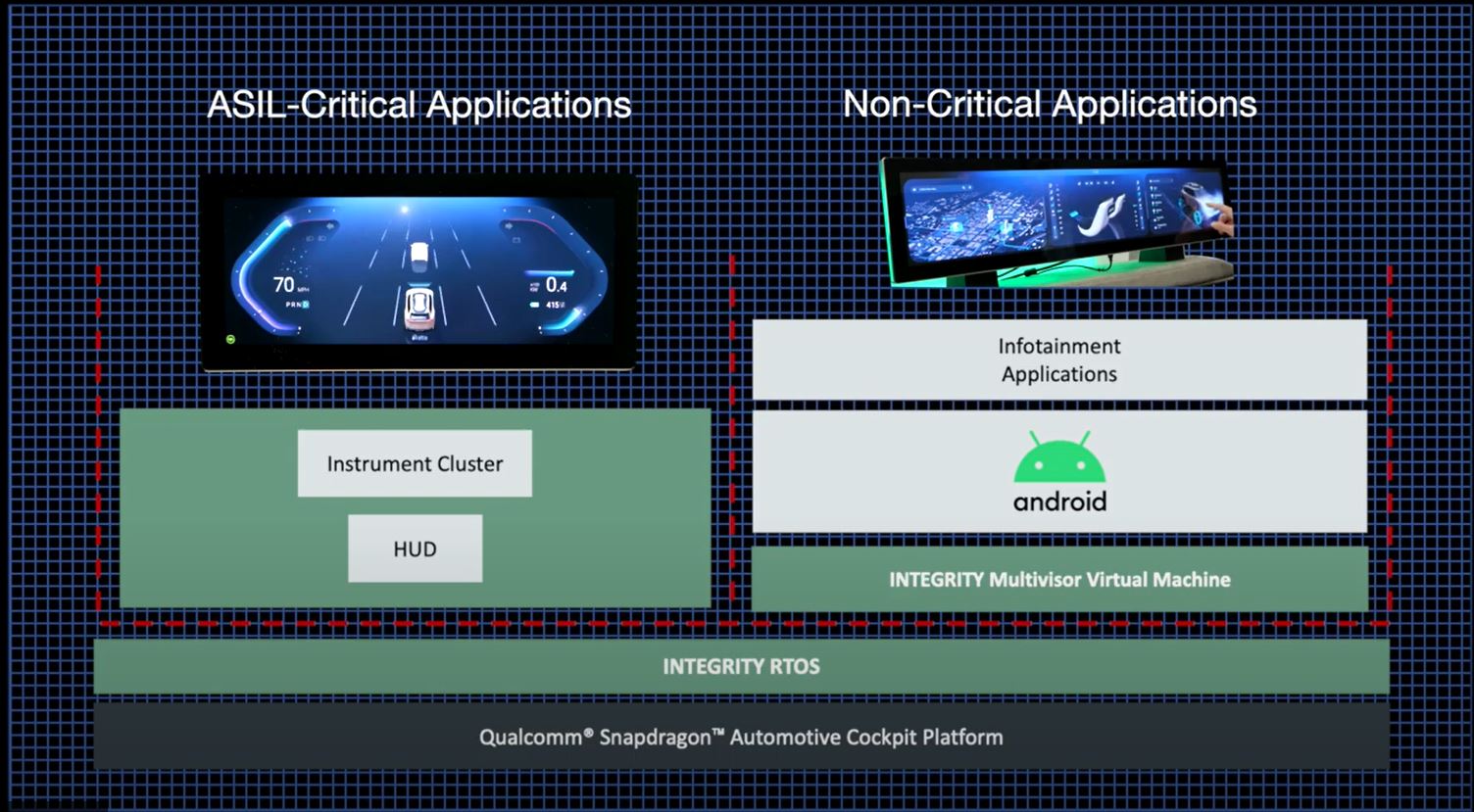

The emerging trend for integrated cockpits is to leverage a single domain controller to consolidate instrument cluster, in-vehicle infotainment (IVI), HUD and driver monitoring functions. That domain controller integrates multiple CPU cores, GPUs and OSes (with or without a hypervisor) to manage different applications in a multi-display environment. The complexity of such a system challenges OEMs to deliver fast boot time and functional safety while offering compelling animations and rich 3D content. Such a system lends itself to a significant integration cost.

With the new R-Car Gen3e, Renesas has made improvements to enable higher integration and simplified software architecture—all aimed at reducing system cost. One such improvement is CR7 Reference Software, which was architected by Renesas to enable peripheral sharing between the Arm Cortex-R7 (“CR7”) real-time CPU and Arm Cortex-A5x domains of the Renesas Gen3e series processor. This sharing enables streamlined development and deployment of graphics with multiple GPUs and OSes.

“With the CR7 Reference Software solution, Altia extends support for the Renesas R-Car Gen3e series to offload real-time parts of automotive applications like 2D gauges to the real-time CR7 core, enabling fast boot time and safe telltale rendering and monitoring in the instrument cluster and HUD,” stated Michael Hill, Altia Vice President of Engineering. “At the same time, Altia’s HMI software can draw and drive high-end 3D content using the Arm Cortex-A5x core. With the CR7 Reference Software solution, Altia will continue to provide high impact, high performance graphics to serve the varying needs of the multiple displays in an integrated cockpit application.”

Altia’s HMI software is available as part of the Renesas CR7 Reference Software. For more information, visit the Renesas R-Car M3e product page. Developers can request an Altia HMI image for their R-Car M3e board by requesting the R-Car Gen3e Safe Rendering Software package.

To learn more about designing, developing and deploying embedded HMIs for automotive applications with Altia, visit www.altia.com/get-started.

About Altia

Altia is a software company that provides graphical user interface design and development tools that can be used from concept to final production code. Our GUI editor, Altia Design, offers development teams the capability to implement a model-based development process enabling clear team communication and accelerated user interface development. Our code generator, Altia DeepScreen, supports a vast range of low- to high-powered processors from a variety of industry-leading silicon providers. Altia generates pure C source code that is optimized to take full advantage of hardware resources. Graphics code generated by Altia is driving millions of displays worldwide – from automotive instrument clusters, HUDs and radios to thermostats, washing machines and medical devices.

Our mission is to get the best automotive, medical and consumer interfaces into production in the shortest time on the lowest cost hardware.

Altia was founded in 1991. Its customers include automotive OEMs and Tier 1s like Continental Automotive, Denso, Stellantis, Ford Motor Company, General Motors, Honda, Renault, Magneti Marelli, Nippon Seiki, Valeo, Visteon and more – plus leading consumer device manufacturers like Electrolux, Whirlpool, NordicTrack and many others.

For more information about Altia, visit www.altia.com or email [email protected].